Hello, reader In this article we will study the Definition and Example of All the Mechanical Properties of Material.

PDF at the end of the article you can download it.

Before moving to our main topic we must have overview on material So,

Whatever thing presents in the world, is material. Either Physical or Non-physical. As a body, mobile, laptop, home, It is all material.

What is Engineering Material?

Material that is used as raw material for any part of construction or manufacturing is an organized way of engineering application is known as an engineering material.

Material science: Science in which new material is discovered Or by using science in the present material, how can we effectively use it, it is called material science.

Classification of Materials:

Properties of Materials:

There are three properties of materials:

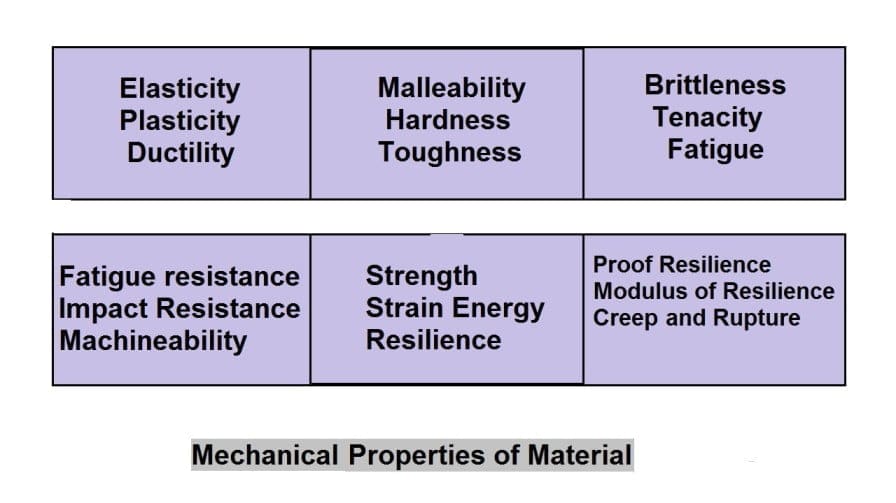

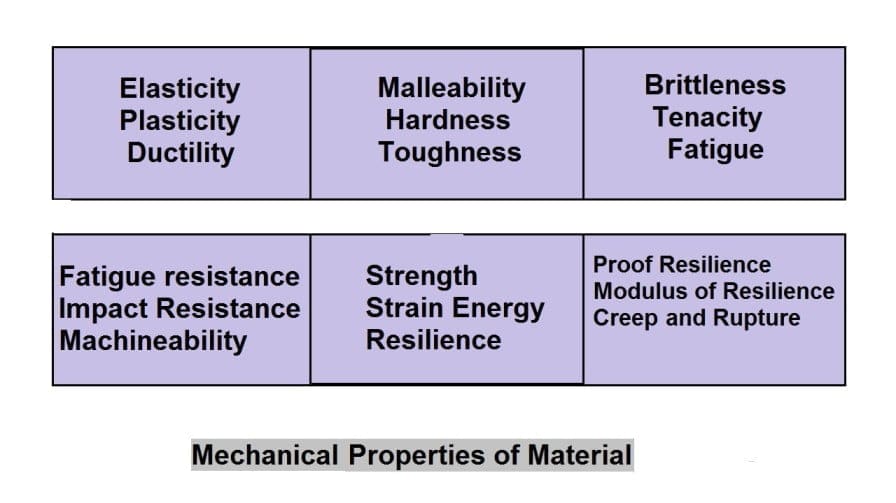

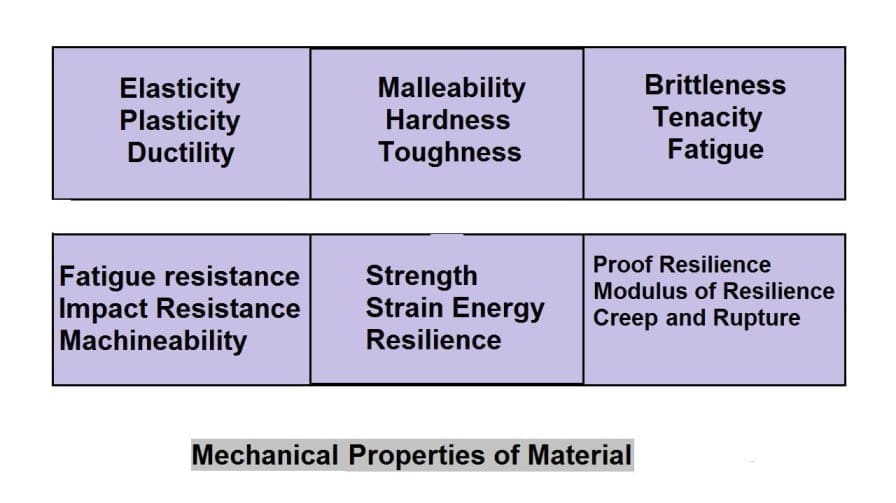

The Mechanical properties of a material affect how they behave as it loaded.

The Mechanical properties of a material are those which affect the mechanical strength and ability of a material to be molded in a suitable shape

The Mechanical Properties include Elasticity, Plasticity, Ductility, Malleability, Hardness, Toughness, Brittleness, Tenacity, Fatigue, Fatigue resistance, Impact Resistance property, Machineability, Strength, Strain Energy, Resilience, Proof Resilience, Modulus of Resilience, Creep, Rupture, and Modulus of Toughness.

Now we will study one by one in simple and understandable language.

Such property of material from which if we pull it and leave it, then it will come back in its shape again, it is called Elasticity. This property is useful for materials used in tools and machines.

E.g. steel is more elastic than rubber.

Such a property of material from which if we pull but it cannot regain its original position when leaving it, then it is called plasticity.

Eg: This property of the material is compulsory for forgings, in stamping images on coins and ornamental work.

Such property of a material that we can pull and make it into long wire form, we call it Ductility. A ductile material needs to both strong and plastic. e.g. The ductile material used in mild steel, copper, aluminum, nickel, zinc, tin, and lead.

If we beat any metal that causes it to spread and form into a sheet form, So we call this property Malleability. A malleable material needs to be plastic but it is not essential to be strong.

E.g. Malleable material is used in engineering practice is lead, soft steel., wrought iron, copper, and aluminum.

Suppose there is a metal and we have to scratch it, The harder the scratch is, the harder our material will be considered.

Suppose we have a material called iron and on the other side is silver aluminum So if we impact on both, the highest impact will be on aluminum because it is a weak metal and its hardness is less.

But if we talk about iron, It will be more difficult to scratch on the sheet of iron if we compare it with aluminum, so hardness will be more of iron.

So a hard material that we cannot easily scratch, is equally hard.

The hardness of a metal is determined by various of tests :

Material that if we bend or twist, how much energy can absorb before it breaks is called Toughness.

The toughness of the material has been decreased when it is heated. So Toughness is properties that provide information about the capacity to absorb maximum energy. In this, we suddenly impact and check how much energy is absorbed at that time.

The toughness of metal is determined by Impact testing machine.

It has a pendulum that suddenly attacks the material, and connects its maximum energy absorbing capacity.

Impact testing has done by two types:

Suppose we have a material and we impact it and it should be broken, without deform is called Brittleness.

Or

If we pull such a material, it breaks instead of pulling it, we call it Brittleness. e.g. Cast iron is a brittle material.

Such material on which we apply pressure, bend, and pull, but do not break it in that condition is called Tenacity.

When a material loads more than a specific load, then there is a chance of failure But in fatigue, Any material fails even at low load if we apply a repetitive load. This failure is known as fatigue.

Fatigue value is many times less than that stress, in which a material has to fail in actual. The factor of fatigue on materials: Less strength, life, and Durability.

E.g. Fatigue property is used for observing In designing shafts, connecting rod, springs, gears, etc.

Causes of fatigue in the material:

1. Dynamic forces

2. Repetitive load/stress

In spite of repetitive loads on a material, it is not broken then it is its fatigue property. E.g. Road

Let’s say we took the material and hit it with a hammer, So the more he can bear the injury of that hammer without breaking, as much his impact resistance will be high.

Such a material that is easy to work on, such as cutting, using a tool, and machining, we call it machinability. E.g. Brass can be easily machined than steel.

If we put a load on metal, it is without changing its shape or if it is able to bear it without breaking it then it is called its strength. So the ability or capacity of a material to withstand or support a load without fracture is called its strength.

If we put a load in a body or material, then the body is elastic up to a particular limit in the stress-strain curve, so the energy that the body stores up to that elastic limit is called Strain energy.

Such material in which the strain energy is stored in the body till the elastic limit only, is called as the resilience. so it is the property of a material to absorb energy and to resist shock and impact loads. This property is essential for spring materials.

How much maximum strain energy stored in material up to the elastic limit is called proof resilience.

If we divide the proof resilience from the volume of body, then it will come out with the Modulus of Resilience.

When we put the material under constant load, for a long time, at high temperature, then the deformation that happens inside it, is called Creep.

It is also known as cold flow. Creep is used for examine in designing internal combustion engines, boilers, and turbines.

Rupture meaning is a break or burst suddenly. Stress rupture testing is similar to creep testing except that the stresses are higher than those used in creep testing.

E.g. pipe or container

Modulus of toughness is defined as the ability of a material to absorb energy in plastic deformation or fracture point.

So This is all about Mechanical Properties of Material. If you want to read the Thermal Properties of the material you can check it. And if you have any doubt then please comment on us.

And If you like the article then Please do share on Social friends.